Micro-machining &

Manufacturing in glass and ceramics

Competitively priced precision machining for microfluidics, microtechnology and watchmaking.

Micro-machining by sandblasting

Grooves, cavities, holes, cut-outs

Micro-machining by sandblasting is a technology in which a jet of micro-particles accelerated by high-pressure air is used to mechanically etch the material. To micro-structure the hard, brittle material, the areas to be spared are masked with an abrasion-resistant material so that the free areas are etched to create cavities or through structures. The sandblast is distributed evenly over the surface of the part to create a homogeneous, anisotropic etch.

With some twenty years' experience, IcoFlex has perfect mastery of this abrasion micromachining technology in a wide range of materials. It is one of the only suppliers of this technology in Europe.

Highlights of our machining technology

- Cutting complex shapes.

- Anisotropic engraving (machining angle of approximately 15° in the glass).

- Protected surfaces retain their original qualities. Direct glass-to-glass sealing and encapsulation capabilities are preserved.

- No induced thermal or mechanical stress.

- No burrs.

- Low cost.

Machining characteristics

- Machining depth: thickness = 2 mm.

- Structure size = 100 µm.

- Structure accuracy linked to the machining mask: ± 5 µm.

- Engraving angle: 10 to 25° depending on the material.

- Roughness: Ra approx. 1.1 µm in glass but varies according to material.

- Aspect ratio for glass: max. 1:1 for structures < 200 µm and 2:1 for structures = 200 µm.

- Engraving accuracy: 20 µm or 10% of depth if depth > to 200 µm.

Machined materials

- Hard ceramic: Aluminium nitride.

- Brittle ceramics: Piezoceramics (PZT), porous ceramics, carbon

- Glass: Borofloat 33, Quartz, special glass (enamel, infrasil, etc.).

- Semiconductors: Silicon.

- Natural materials: mother-of-pearl, semi-precious stones (onyx, lapis lazuli, etc.).

- Metals: Precious metals in thin layers and sintered oxides (ferrite).

- Plastics: PMMA, Epoxy, PEEK.

Other mastered technologies

- Glass/glass or glass/silicon seal (with or without intermediate layer).

- Metal deposition by evaporation or electroplating.

- Formulation of polymer materials (photosensitive polymers, adhesives, dyes, etc.).

Our micromachining and manufacturing offer

-

Optimising the design or conception of your parts

-

Feasibility study

-

Micro-structuring and cutting of parts in sheets not exceeding 200 mm

-

Production of a prototype of a few hundred plates per month

-

Contact us for more information →

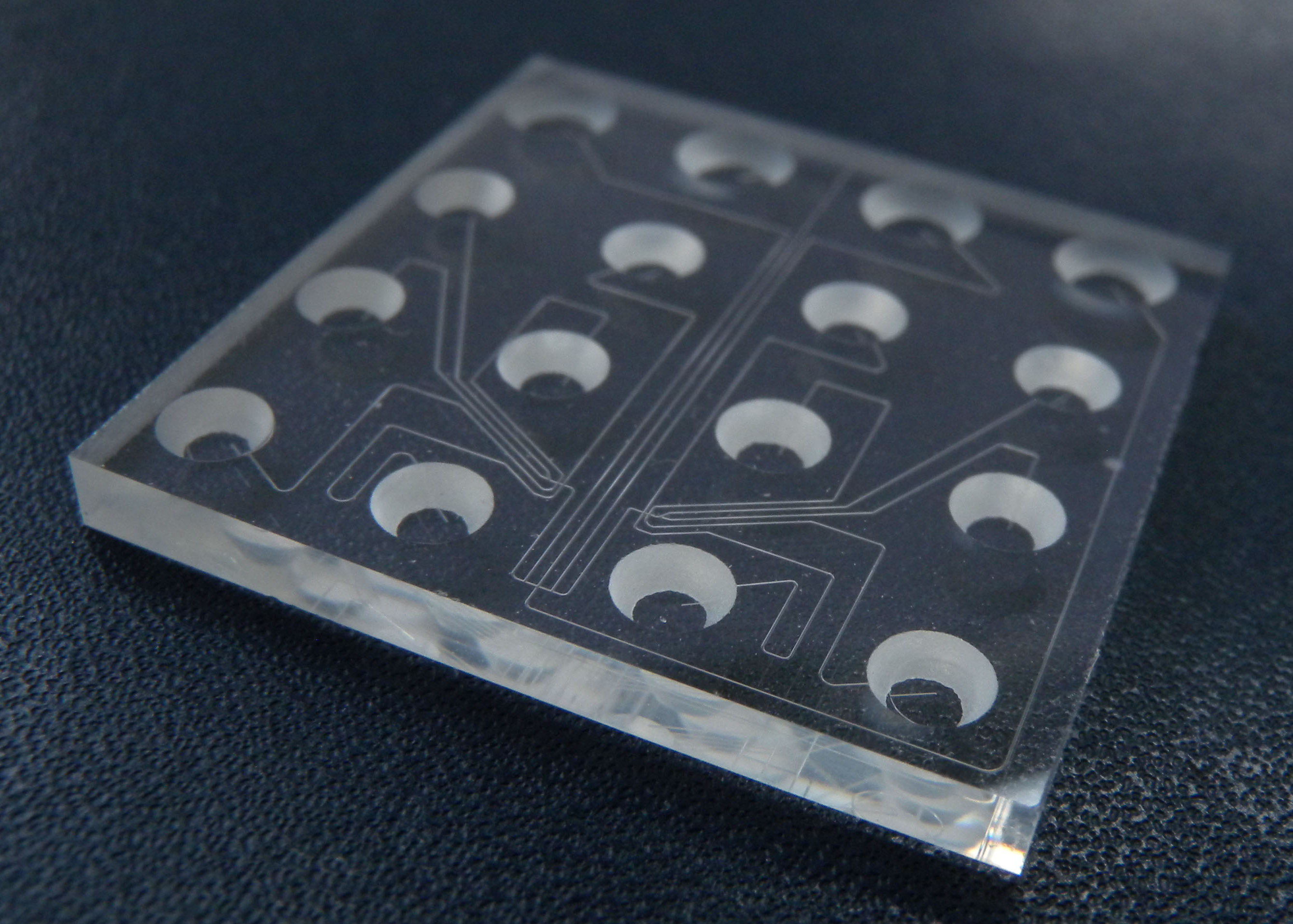

Glass micro-fluidic chip

Micro-channels and micro-holes 200 µm wide in glass

Machining watch dials with coloured glass

Series production